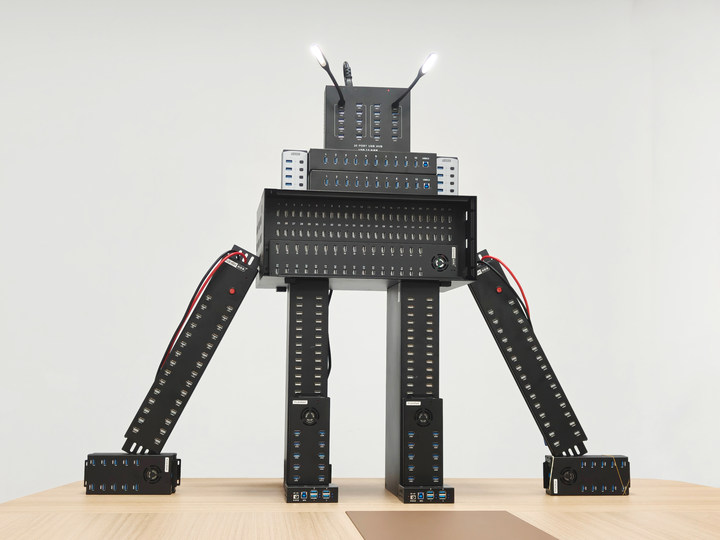

As robotics technology rapidly evolves, industrial-grade hubs have emerged as critical components in ensuring seamless communication, power delivery, and system reliability. At Sipolar, our usb hub is designed to meet the rigorous demands of robotic applications across industries. Here’s how industrial hubs are transforming robotics:

Table of Contents

Toggle1. Real-Time Control and Communication in Robotic Clusters

In automated manufacturing lines, multiple robots must collaborate with split-second precision. Industrial hubs provide high-speed, low-latency networks to synchronize tasks like welding, assembly, and material handling. For example:

Automotive Manufacturing: Our hubs enable 5Gbps data transfer between welding robots and autonomous guided vehicles (AGVs), ensuring real-time positional data exchange to prevent production delays.

Collaborative Robotics (Cobots): Sipolar hubs support dynamic path planning and obstacle avoidance by maintaining stable communication between cobots and central control systems, enhancing human-robot safety.

2. Intelligent Logistics and Warehouse Automation

AGVs and sorting robots rely on industrial hubs to optimize operations in smart warehouses:

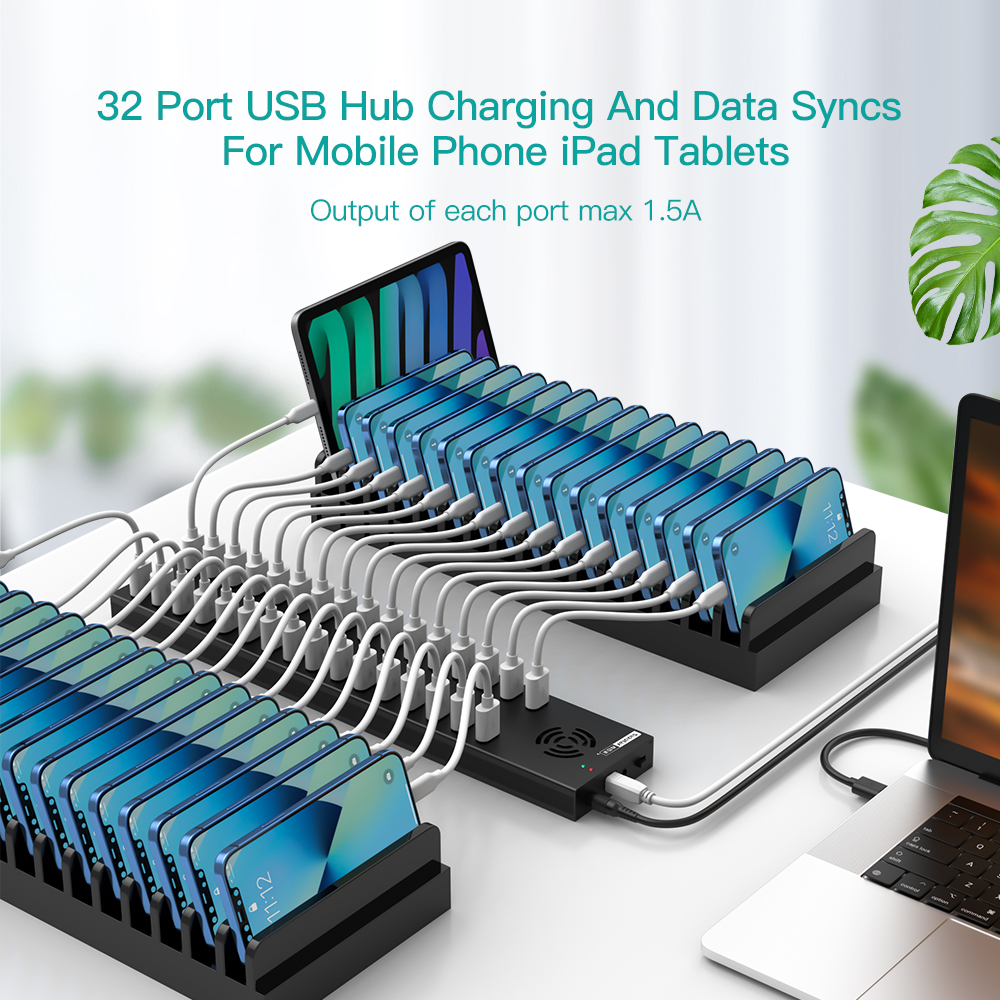

AGV Fleet Management:Many of our usb hub design connects AGVs to centralized systems, monitoring battery levels, cargo status, and route efficiency in real time.

High-Speed Sorting: With 5Gbps bandwidth, our hubs ensure rapid transmission of visual recognition data to sorting robots, enabling 500+ precise actions per minute.

3. Deployment in Extreme Environments

Industrial hubs excel in harsh conditions where standard hardware fails:

Mining and Metallurgy: Built with cold-rolled steel and IP67-rated protection, our industrial usb hub withstands dust, vibrations, and temperatures up to 80°C, maintaining connectivity for unmanned mining robots.

High-Temperature Workshops: cooling systems prevent overheating in metal smelting or glass production facilities.

4. Remote Monitoring and Predictive Maintenance

Integrated IoT networks powered by industrial hubs enable proactive system management:

Fault Diagnostics: Sensors in robots transmit vibration and temperature data via hubs to cloud platforms, predicting failures in motors or reducers before downtime occurs.

5. High-Precision Manufacturing Applications

For micron-level accuracy in semiconductor or aerospace production:

Vision-Guided Assembly: High-resolution image data is transmitted at 5Gbps to guide robotic arms in delicate part positioning.

Laser Processing Synchronization: Hubs ensure millisecond-level alignment between robotic trajectories and laser parameters, eliminating machining errors.

Why Choose Sipolar’s Industrial Hub?

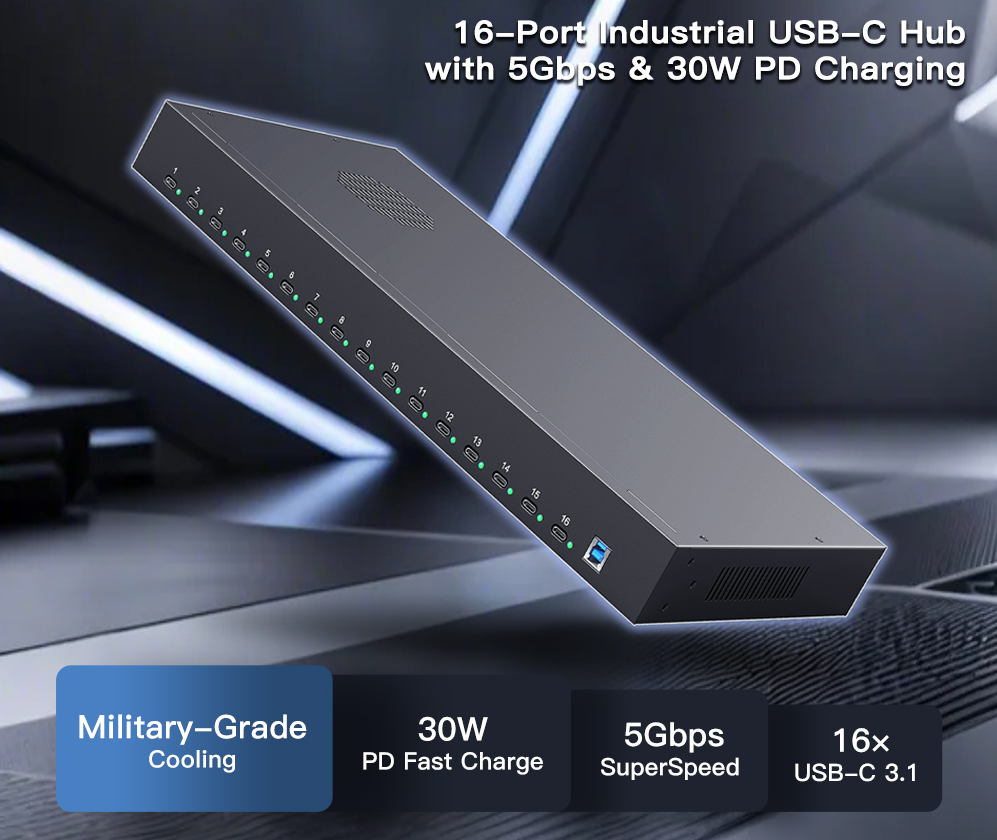

Robust Connectivity: n USB ports with 5Gbps speed and PD charging per port.

Military-Grade Durability: 1.2mm steel casing, adaptive cooling, and EMI shielding.

Smart Management: LED status indicators and redundancy power inputs for uninterrupted operations.

Market Outlook and Sipolar’s Commitment

The global robotics market is projected to reach $235.1 billion by 2025, with industrial automation driving demand. As industries embrace Industry 4.0, Sipolar remains at the forefront, developing hubs that support emerging trends like Time-Sensitive Networking (TSN) and edge computing for AI-driven robotics.

Explore how the Sipolar Industrial Hub can elevate your robotic systems: [Contact Sipolar Today].

Sipolar — Powering the Future of Industrial Robotics.